VALIDATION OF PASSIVATION PROCESS USED FOR METAL SURFACES

TANK INTERIORS [VESSELS, CONTAINERS AND EQUIPMENT]

Aim : To establish the method to evaluate that the pharmaceutical equipment and high purity water pipe linescontact surfaces are rendered non reactive, additive or absorptive so that drug product is not adversely altered.

Brief description of Passivation Process:

1. Solvent decreasing

2. Water Washing

3. Passivation ( acid wash)

4. Final Water Rinse.

Treat the metal part at RT with solvent or water-soluble detergent and remove dirt, oil, grease from the surface. Wash the decreased surface with water at RT to remove loosened particles and detergents.

Passivate the metal surface with suitable passivating agent (oxidizing agent). This will remove free ions, metallic residue, oxides and other corrosion products.Rinse the metal surface with water to remove all extractable residues.

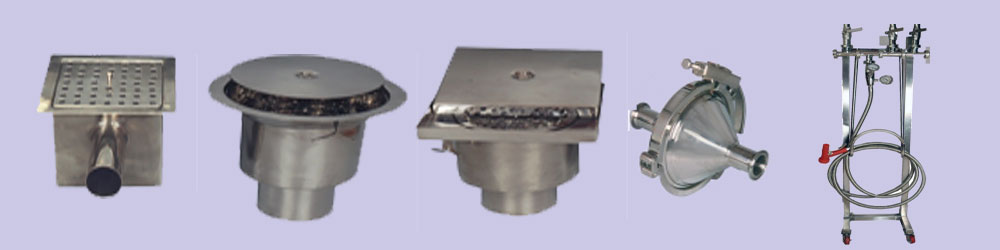

PASSIVATION OF TANK INTERIORS

[VESSELS, CONTAINERS AND EQUIPMENT]

Method used for passivation: Cleaning and passivation solutions are sprayed onto the interior surfaces of the vessels, containers and equipment for minimum of 30 minutes per each rise stage. Repeat each stage three times.

Testing Method:

Pour 1000 ml de-ionized water over the surface at RT collect for testing. Repeat the step three times for each of the steps mentioned below.

A. Filter through 0.2 to 0.5 filter and inspect.

B. Check the conductivity before spraying and after spraying.